FITNESS EQUIPMENT PREVENTIVE MAINTENANCE FOR CHARLOTTE, NC AND SURROUNDING AREAS

ROUTINE MAINTENANCE IS VITAL TO THE LONGEVITY AND PERFORMANCE OF YOUR EQUIPMENT

Your fitness equipment is an investment....

"Just as proper diet and exercise help human beings live healthier lives, preventive maintenance is the key to getting the most out of exercise equipment. Preventing service calls and keeping exercise machines running with minimal downtime requires more than just wiping down equipment and reporting malfunctioning units to your technician. A regular program of care truly can extend the life of your equipment and save money in the long run."

Chris Keel, Life Fitness Manager of Technical Support and Training

"Regardless of the number of machines in your fitness center, and no matter what their workloads, a concerted preventive maintenance effort is crucial. Customers will be content that their favorite equipment isn't constantly being repaired, and the facility will be safer because potentially dangerous malfunctions are identified before machines can cause injury. Finally, machines that run longer with less downtime and fewer repairs also will keep your facility's budget in shape."

Chris Keel, Life Fitness Manager of Technical Support and Training

"Just as proper diet and exercise help human beings live healthier lives, preventive maintenance is the key to getting the most out of exercise equipment. Preventing service calls and keeping exercise machines running with minimal downtime requires more than just wiping down equipment and reporting malfunctioning units to your technician. A regular program of care truly can extend the life of your equipment and save money in the long run."

Chris Keel, Life Fitness Manager of Technical Support and Training

"Regardless of the number of machines in your fitness center, and no matter what their workloads, a concerted preventive maintenance effort is crucial. Customers will be content that their favorite equipment isn't constantly being repaired, and the facility will be safer because potentially dangerous malfunctions are identified before machines can cause injury. Finally, machines that run longer with less downtime and fewer repairs also will keep your facility's budget in shape."

Chris Keel, Life Fitness Manager of Technical Support and Training

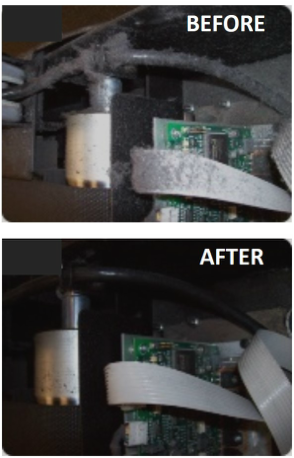

The primary cause for fitness equipment failure is the friction from dust, dirt and perspiration as well as the lack of lubrication. Routine maintenance can identify potential failures before they occur, eliminating un-scheduled service calls and equipment down-time. Industry professionals recommend that maintenance be performed every 250 hours of use to ensure equipment safety and reasonable service life.

Our Preventive Maintenance Program is a great way to get the most out of your equipment investment. We work with you to set up monthly, quarterly or bi-annual routine maintenance schedules.

Our Preventive Maintenance Program is a great way to get the most out of your equipment investment. We work with you to set up monthly, quarterly or bi-annual routine maintenance schedules.

|

General Preventive Maintenance Includes the Following:

|

Detailed Preventive Maintenance Per Equipment

|

TREADMILL:

|

ELLIPTICAL / STEPPER

|

BIKE:

|